Following various issues caused by the obsolescence of its installation, this construction materials supplier has enlisted Automation & Services to renew the equipment on its site, aiming to better serve its customers.

Due to recurring issues caused by aging equipment, BigMat BATIDAL in Battice decided to enlist Automation & Services to modernize its facilities.

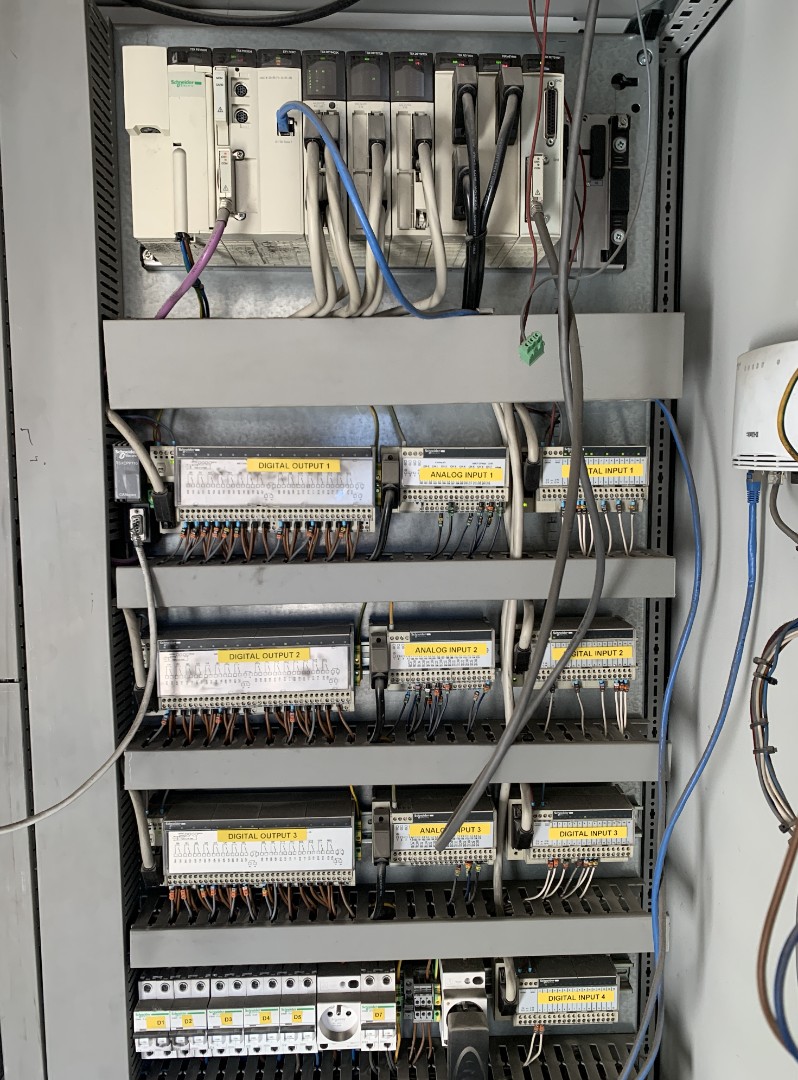

Automation & Services had a clear mission: to make the concrete batching plant reliable. To achieve this, the teams first analyzed the plant's operation and compiled all available documentation. Due to a lack of information, the work had to be done on-site, exploring every corner of the installation. After mapping all sensors and establishing the workflow, the focus shifted to the electrical equipment, especially the control panel. The old automation system was replaced with a Siemens model, as was the HMI allowing the launch of the plant and management of the concrete quantity delivered. Several recipes were integrated, enabling the operator to adjust the mix according to requirements. The ability to control the plant remotely was also implemented, in a short distance, ensuring installation safety.

Automation & Services takes pride in the success of this project, significantly improving the efficiency of BigMat BATIDAL. The tasks undertaken include:

- Upgrading the plant documentation

- In-depth study of its operation

- Replacement of defective equipment

- Software development

- Installation of a new routine meeting the client's needs

- Easy access to plant control through a reliable HMI

- Remote management

- Delivery of updated plans and documentation.

For the modernization of your aging installations, feel free to contact us: